As a makerspace manager, one of the absolute best parts of my job is helping my students design their own custom robotics projects. Over the years, I began to realize that while most of my students were excited to learn the basics, there were some more advanced robotics tools that they assumed were way over their heads! This was especially true when it came to integrating and calculating the forward and inverse kinematics in their projects. This led me to develop a series of makerspace workshops with a simple goal: demystifying inverse kinematics! Whether you’re working on animatronics, humanoid or quadruped robots, or even a robotic arm project, inverse kinematics can help take all kinds of fun projects to the next level. Even better, getting started is easier than you might think!

When it comes to programming devices like servo motors with a microcontroller, getting that motor to move to a specific position is pretty easy! A few lines of code, some wires, and you’re done!

But what if you’re working on something like a robotic arm project? What if we needed the end of our robotic arm to move to a very specific location? We could certainly slowly figure out what angles we would need from all of our motors through trial and error, but that could take quite a while. That’s where inverse kinematics comes in! With just a little bit of math, we can write a program that will allow us to use any coordinate point we want as an input, and our code will calculate the exact angles our motors need to move to in order to move the end of our robotic arm to our goal coordinate.

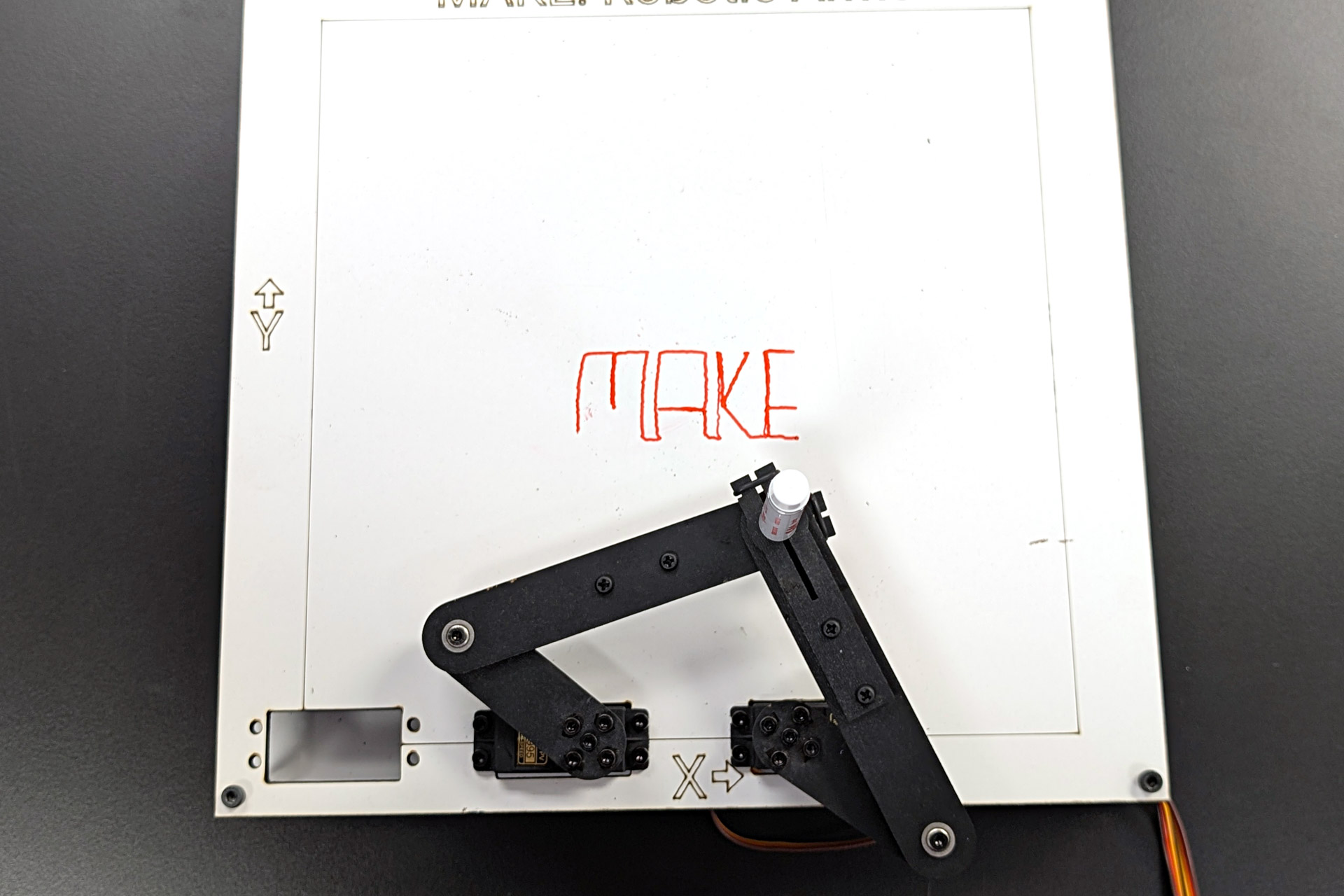

Once we have a robot that can move anywhere we want quickly and accurately, there are all kinds of fun things we can build, like building the legs of a robotic dog, the arms of a humanoid or an animatronics robotics project, and even building a DIY draw bot. In fact, that’s the goal of this article! We’re going to start by assembling a four-link robotic arm that will serve as the structure of our robot. Then we’ll take a look at a little math we’ll need in order to develop our inverse kinematics equations, and then we will put it all together to make a fun drawing robot!

One quick note, there are many different ways to build a drawing robot, and there may be more efficient methods out there, such as the linear assemblies found in devices like laser cutters and 3D printers. This project is much more about understanding the relationship between inverse kinematics and robotic joints and links to build a fun robotic arm project, as opposed to simply achieving the highest possible accuracy.

Ok, let’s get building!